LIFE PROOF BOATS constructs all of our vessels within the Bremerton Industrial Park, located in Washington State. We have expanded within four facilities and have approximately 45,000 square feet of total manufacturing space. We utilize a dedicated facility for welding, a separate dedicated facility for all of our collar manufacturing & upholstery, and two facilities dedicated to system integrations.

Premium Materials

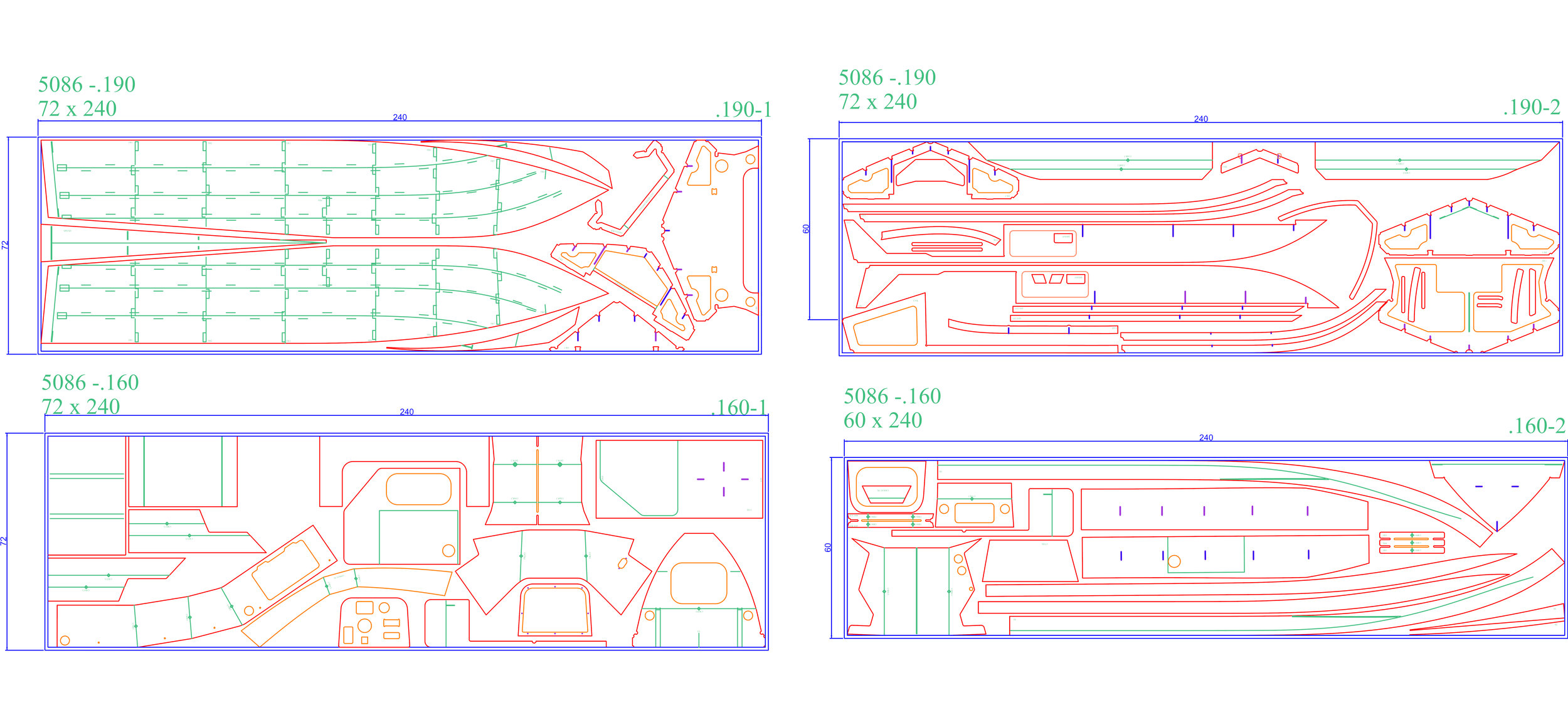

Because our boats are used in the toughest of environments, they are built stronger. That is why we exclusively use 5086 H116 Grade Aluminum plates in all of our boats. A lot of other builders choose to use 5052 alloy aluminum because it can cost up to 20% less. But 5086 H116 is much stronger in a welded condition and more durable. Even our custom hull strake extrusions are made from 5086 alloy aluminum.

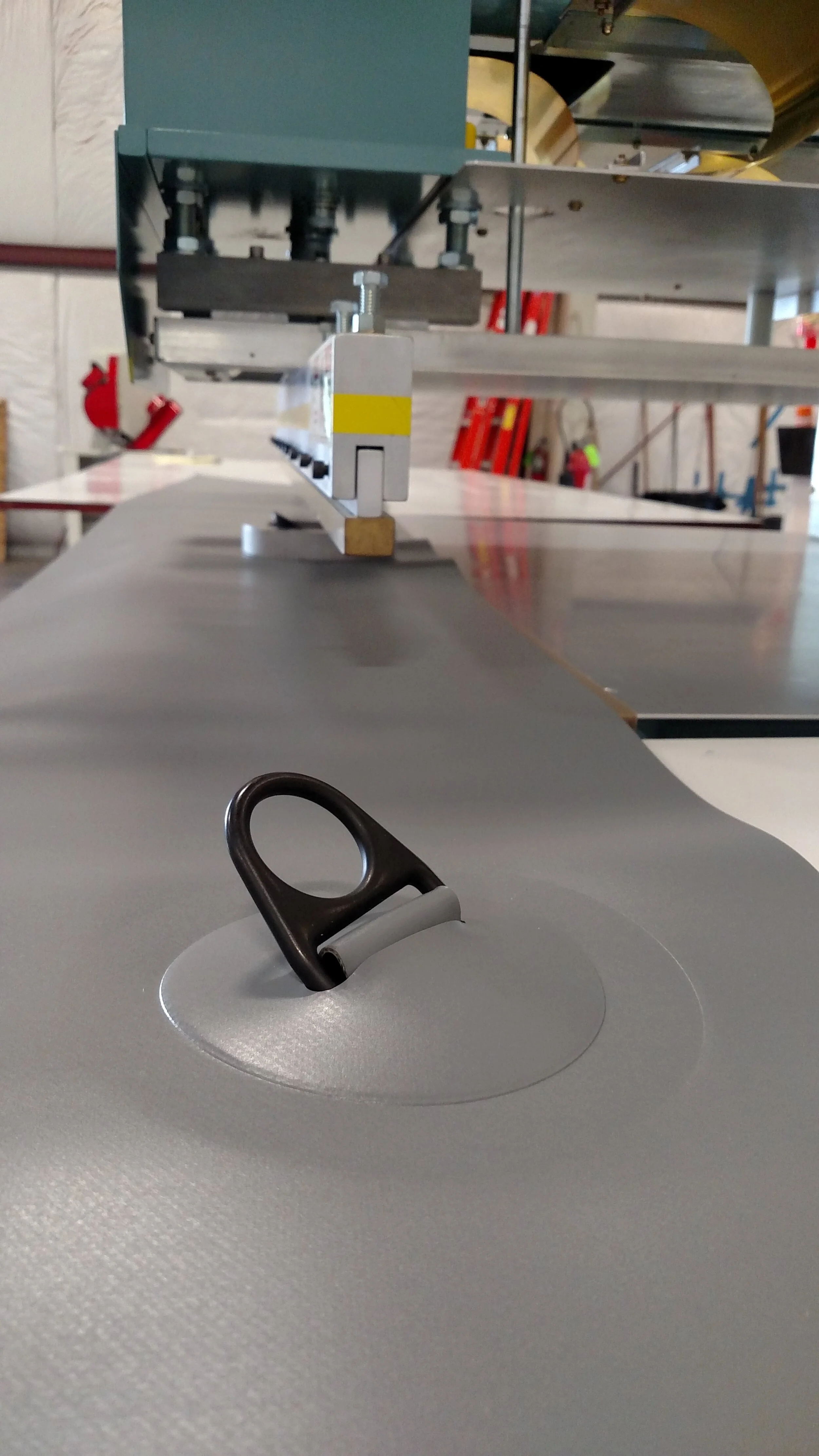

All of the parts used to build Life Proof Boats are cut on a CNC router machine. We choose CNC router cut parts over water jet or plasma cut parts because a router provides a more pure surface on the cut edge. Water or plasma machines often leave a very porous edge surface, which can lead to microvoids in the welding process.

With many of our competitors looking to build at the lowest cost it often means they sacrifice quality in the materials they choose to use. We look at it differently. If quality is a pillar of your brand, then people will choose it for its known quality. Our quality is our difference and will always be a core to who we are. We have spent countless hours looking at materials and components to ensure our boats are built using the best industry-available parts.

All of our parts are also cut on a CNC router machine because of the higher quality surface edge it provides. Water or plasma machines often leave a very porous edge surface, which can lead to microvoids in the welding process.

Higher Standards

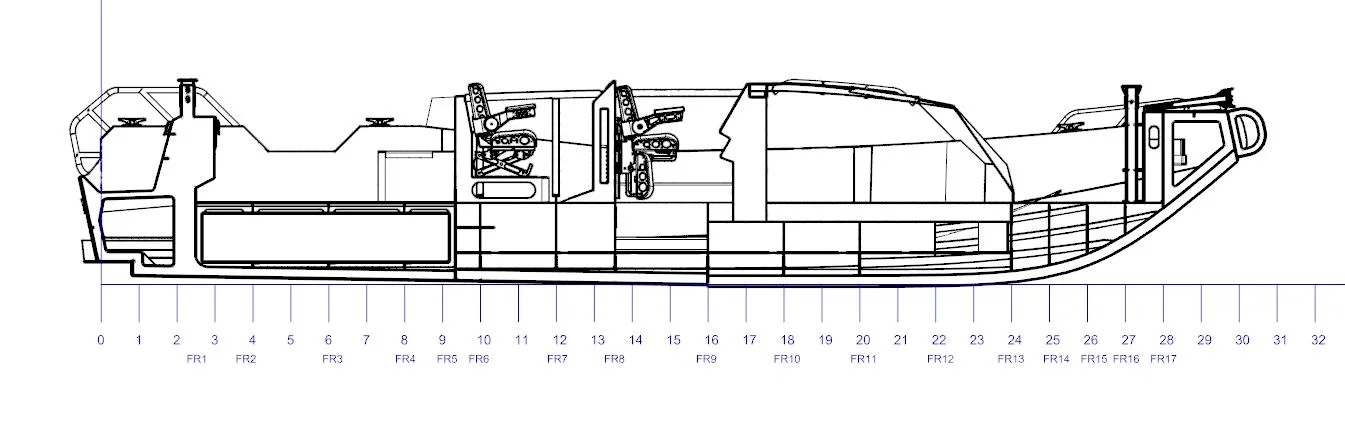

Before starting a new design we work through principles in naval architecture to ensure all our vessels have the correct structural design, proper LCG & VCG & TCG locations, and proper waterline location.

We engineer all of the boat’s structural pieces to "egg crate" or interconnect. That is to ensure a perfect fit and add rigidity to the platforms.

Every piece of aluminum in the boat is engineered to be used in a specific location for a specific function. Each part is purpose-built.

Built Stronger

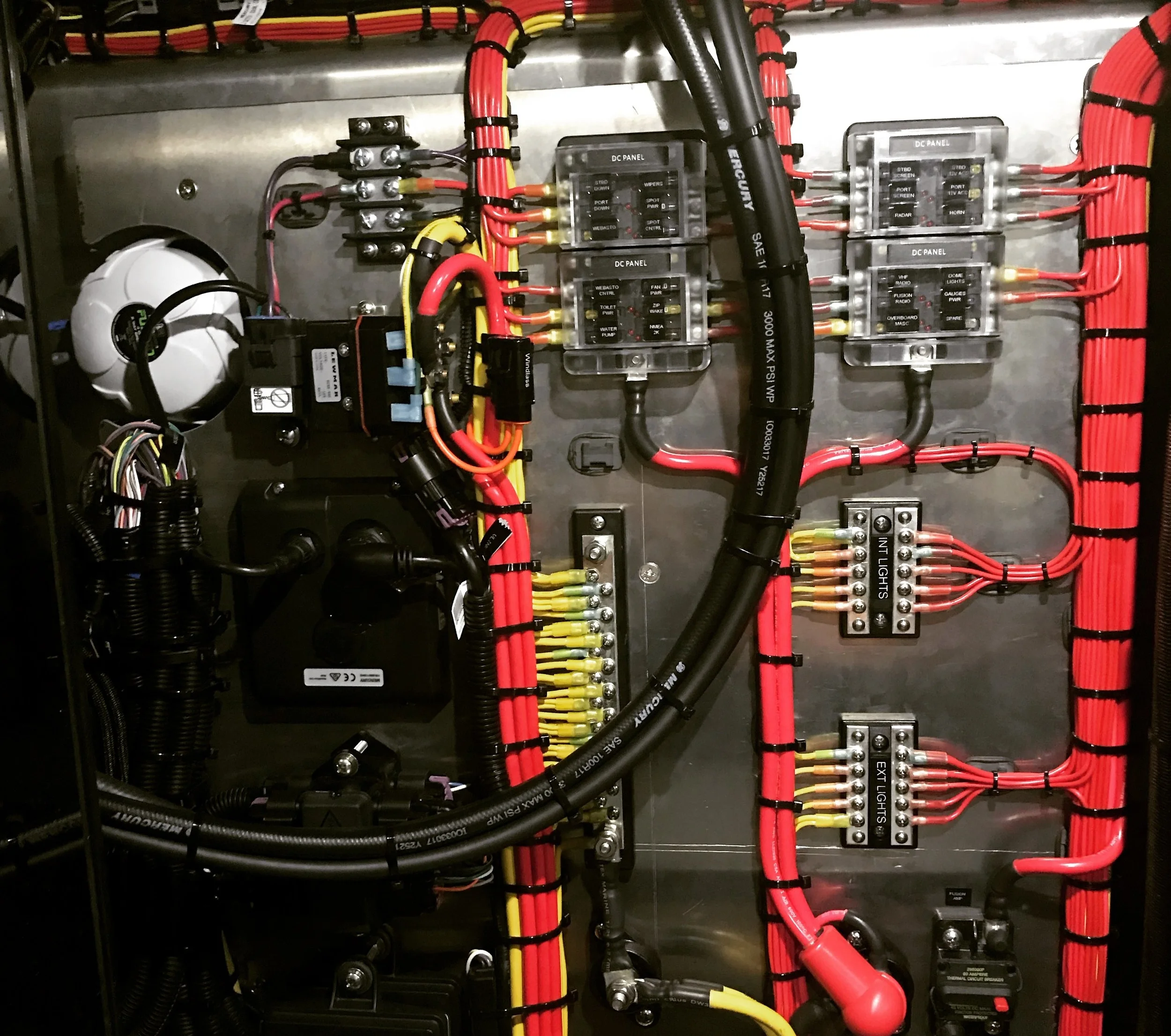

Our employees are the best and brightest in the industry. We have assembled a team of people who are highly skilled and highly educated in what it takes to build a high-quality product that will last for generations. Our boats are built tougher because they are driven tougher.

We choose to build our boats on a hull jig because it allows us to keep the hull plates extremely straight and true. The hull is the foundation that influences how the boat handles, drives, feels and performs. A true hull shape is critical. Running longitudinally down the center of the boat you will find two full-height frames. These frames create one of the strongest known beam designs known to structural engineering; an I-Beam. This I-Beam design disperses the stresses from heavy slamming loads.

Day 1 - Setting the Transom and Laying Framing

Typical framing layout

Side Sheets Installed, Prepping Deck Layout

Hull Weldout on a 27ft Full Cabin

A Virtually Unsinkable Boat

Safety is paramount to what we do. We incorporate industry-leading safety features into all of our boats. These features include our patented collar systems, self-bailing decks, and reserve flotation foam strategically located in hull compartments.

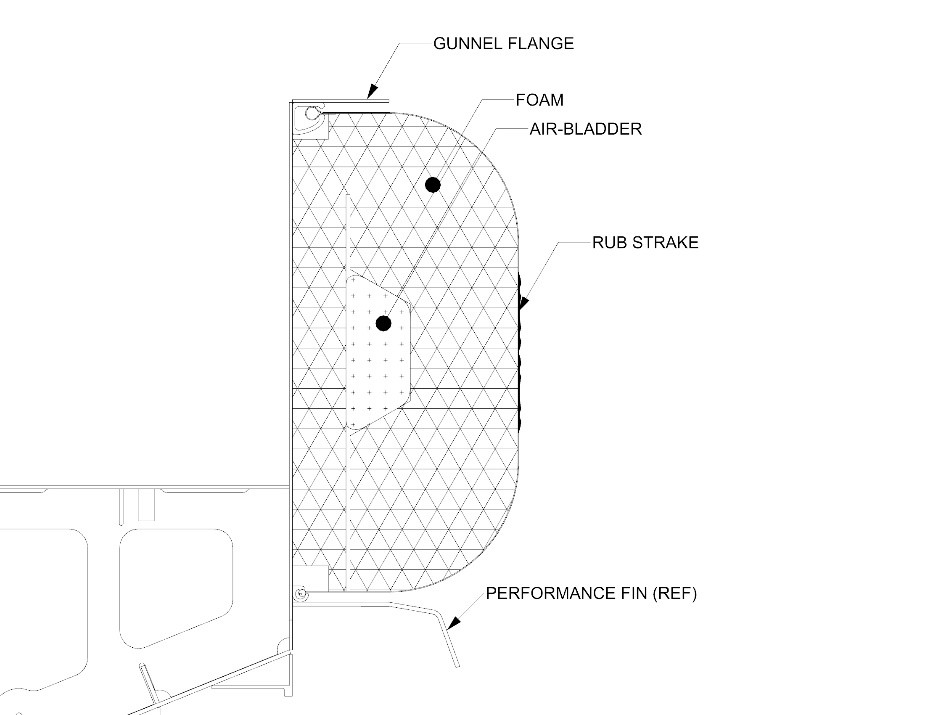

The Life Proof Boat collar system makes the boat virtually unsinkable. It is a clear identifier for all of our vessels. The collar runs the boat's entire length and stabilizes the boat no matter the conditions. It's like a life jacket for your boat and is strategically designed to our boat designs. Our extensive history of building collared boats for first responders, and government agencies gives us an advantage in design.

Our self-bailing decks are passive and work purely through gravity. With our design, a deck completely filled with water will clear in under one minute.

We fill every void in the hull with fiberglass FR “fire-resistant” bags. The bags contain the same closed-cell foam used in our external collar systems, to add additional flotation if there was ever a hull breach.

Intelligent Features

The foam we use is not typical foam. The EPE (expanded polyethylene) foam provides over 60 lbs of flotation per cubic foot. It is incredibly lightweight, absorbs virtually zero water, is resistant to chemical & fuel exposure, resists impact, and has excellent shape memory.

Bow Pulpit: Integrated under the bow door is an anchor locker system with an anchor pulpit/roller. The anchor locker is self-draining and can be configured with an integrated windlass.

Performance Fins: With Inventech Marine's performance fin, located below the collar the boat stays flat in the corners. They provide unmatched performance and greatly reduce heel in corners. IMS has developed and integrated a FWD canard in the shoulder of the vessel for additional safety and performance in mixed sea-state cornering.

Bow Door: A manually lowering bow/dive door with folding/ladder is a clean and simple integration providing greater operational capability. No maintenance design and easy-to-use over-center locking safety latch securing the door during normal operation. Provides accessible beach or water access.